Excess Flow Check Valve Download Brochure

Download Brochure

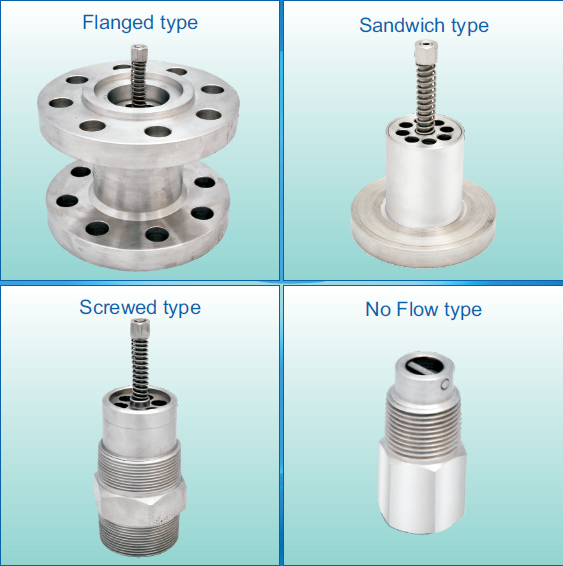

Excess flow check valve is installed as an emergency shut off valve to achieve safe control over fluid flow parameters of flow and differential pressure.

Product Features :

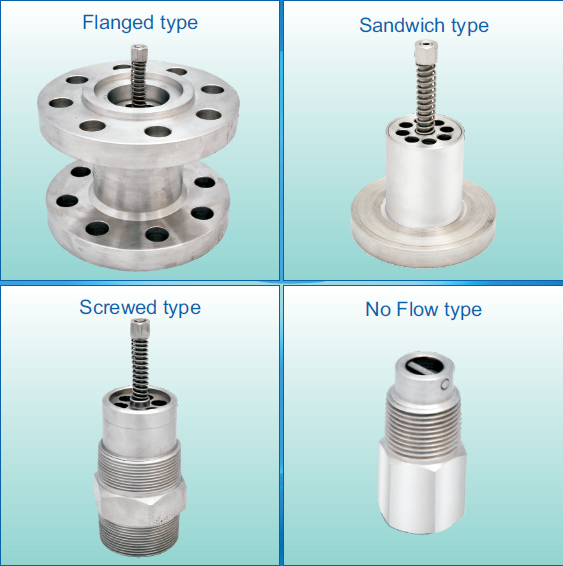

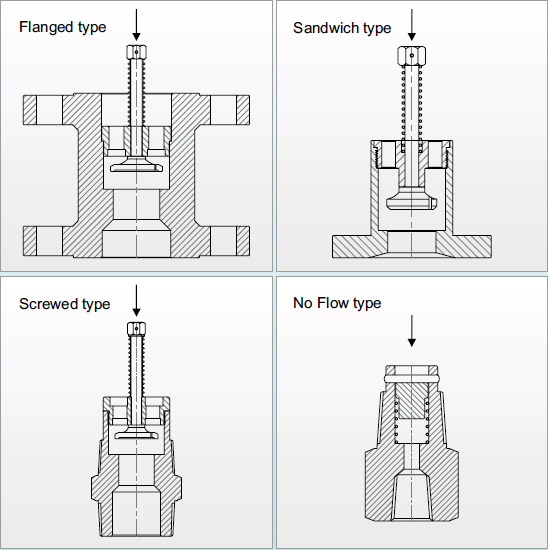

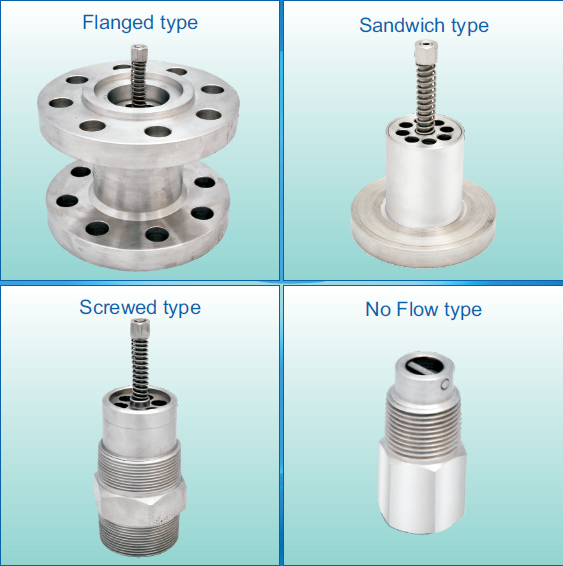

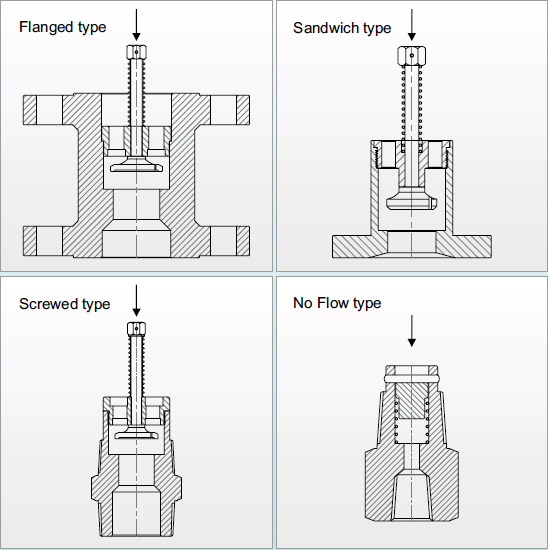

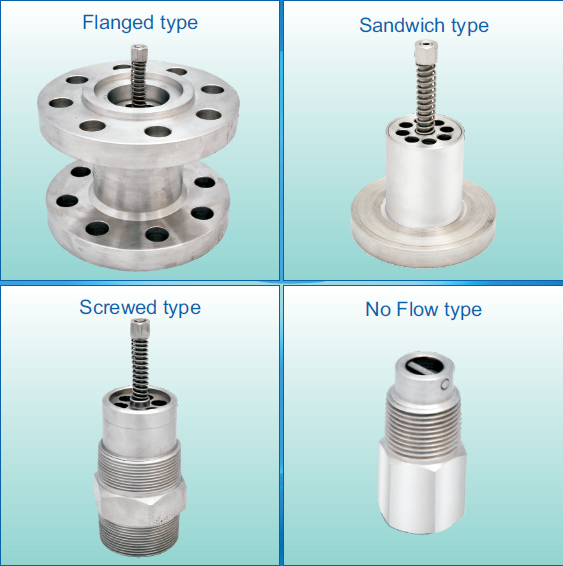

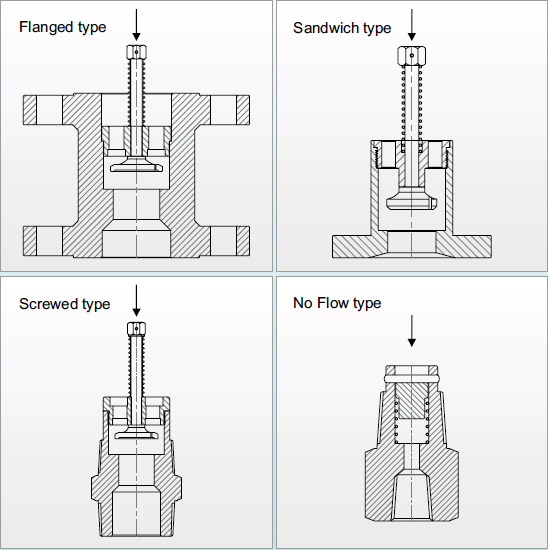

- Available in multiple configurations of screwed end, flanged end, sandwich type and no flow type for instrumentation nozzle.

- Available size range: ½” NPT to 4” NPT in screwed type, ¼” NB to 36”NB in flanged type, ½” NB to 16” NB in sandwich type and ⅛ NB to 2” NB size in no flow type.

- Primarily used in pressure vessels, pipelines, chemical plants, ship-shore line/cross country pipelines, bottling plants, loading arms, discharge lines of pump, petrochemical units and other applications.

- Applications in LPG, Propane, Ammonia, Ethylene Oxide, MMA/DMA/TMA, Chlorine, Propylene Oxide, Nitrogen, Oxygen and other compressed fluids.

- Safety device for auto shut off triggered by conditions of fluid flow and differential pressure across the valve.

- Available in various material of construction to suit fluid applications ASTM A216 WCB/ASTM A105/ASTM A350 LF2/stainless steel 304/316/316L and Monell to list a few.

- Designed as per international standards such as BSEN - 13175, Static and Mobile Pressure Vessel Rules (Unfired) 1981 and relevant safety codes and standards.

- Approved by the Chief Controller of Explosives, Nagpur (Government of India). Inspected/Certified by agencies of global repute, like EIL, RDSO, SGS, ABS & BV, etc.

- Manufactured and supplied around to 1,50,000 excess flow check valves in India and around the globe for a variety of applications in our 30 years experience in this field.

Technical Notes :

- 1) The excess flow valve permits the flow of vapour or liquid in either directions. The flow is controlled only in

one direction.

- 2) If the flow through the valve exceeds the predetermined value, the valve will shut off flow to ensure safety of the circuit.

- 3) The design of the excess flow check valve is made to suit client's requirements of flow based on process parameters of flow and ressure.

- 4) The excess flow check valve is designed for normal flow rate, peak operating flow rate and closing flow rate.

- 5) The closing flow rate is 20-25% higher than the peak operating flow rate. The normal operating flow rate is lower than or equal to peak operating flow rate.

- 6) Testing of excess flow valve is done using water as test medium following International codes & standards.

Safety Relief Valve Download Brochure

Download Brochure

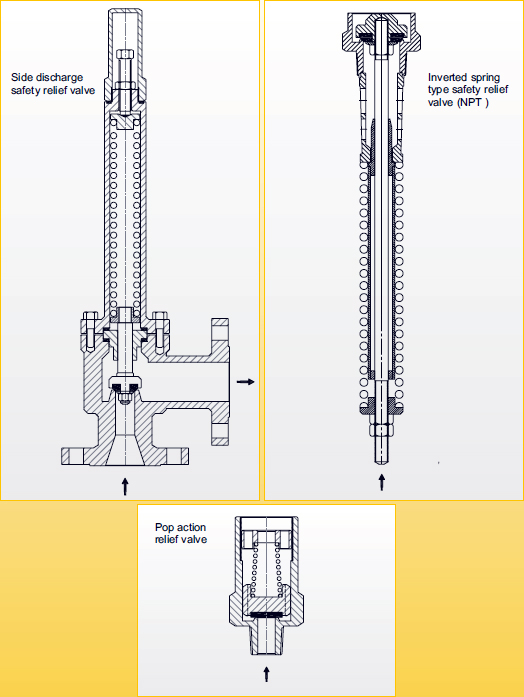

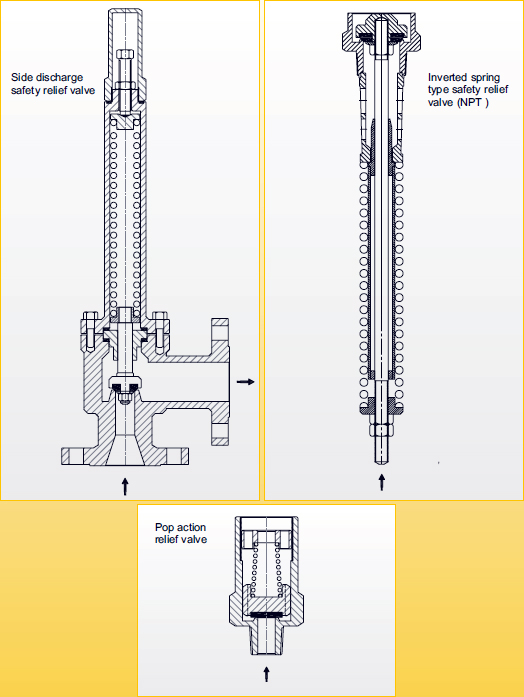

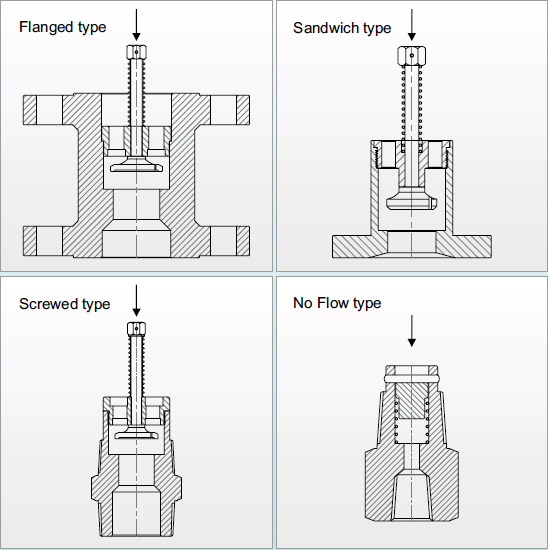

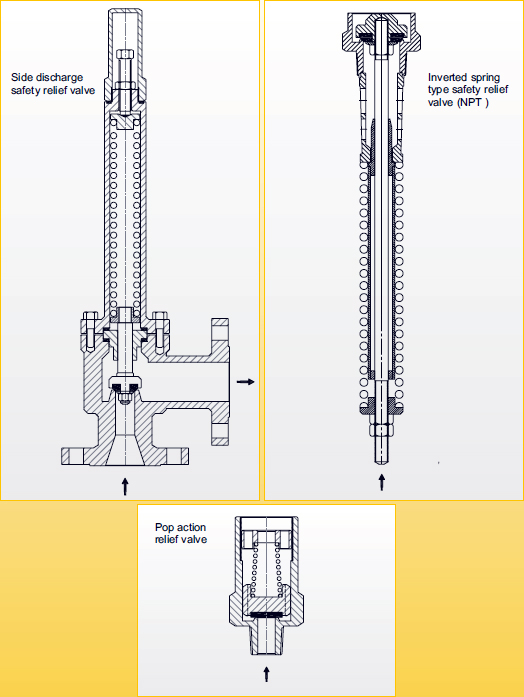

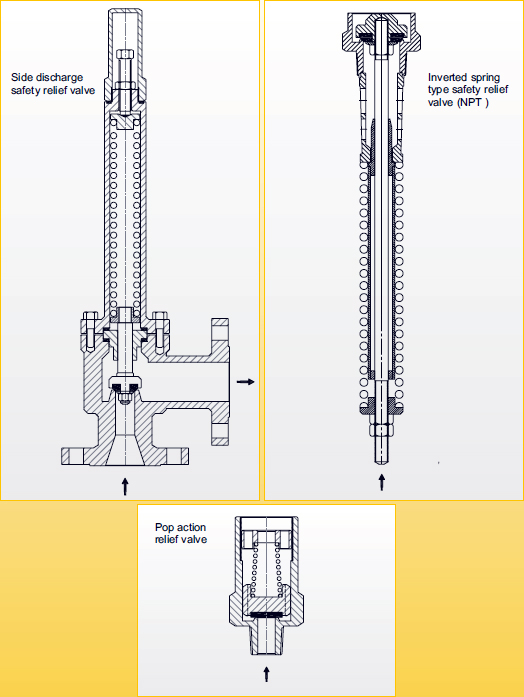

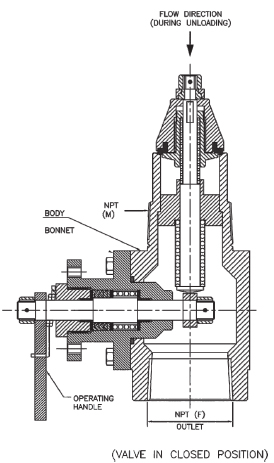

Safety Relief Valves are spring loaded valves. They are used to provide over-pressure relief for the protection of the vessel / pipeline / tanks / process equipments from unsafe conditions. The valve normally remains in shut condition due to force of the spring and when there is a rise in pressure, the force of the spring is overcome actuating the valve to open condition to release the excess pressure.

Product Features :

- Available in multiple configurations of screwed end & flanged end (side discharge). Pop action safety valve which are used for instantaneous quick discharge are manufactured for typical TSV applications.

- Available size range: ¼” NPT to 3” NPT in screwed type, ½” NB x ¾” NB to 150mm NB x 200mm NB in flange type, ½” NPT to 3” NPT in Pop action safety relief valve.

- Primarily used in pressure vessels, pipelines, chemical plants, ship-shore line/cross country pipelines, bottling plants, petrochemical units and other applications.

- Applications in LPG, Propane, Ammonia, Ethylene Oxide, MMA/DMA/TMA, Chlorine, Propylene Oxide, Nitrogen, Oxygen and other compressed fluids.

- Safety device for over pressure relief is designed as per customer requirements of service, set pressure & sized as per relieving capacity requirement of the vessel / process.

- Available in various material of construction to suit fluid applications - ASTM A216 WCB/A105/ASTM A350 LF2/stainless steel 304/316/316L and Monel to list a few.

- Designed as per international standards, Static and Mobile Pressure Vessel Rules (Unfired) 1981 and relevant safety codes and standards.

- Approved by the Chief Controller of Explosives, Nagpur (Government of India). Inspected/certified by agencies of global repute, like EIL, RDSO, SGS, ABS & BV, etc.

- We have manufactured and supplied around to 1,00,000 safety relief valves in India and around the globe for a variety of applications in our 30 years experience in this field.

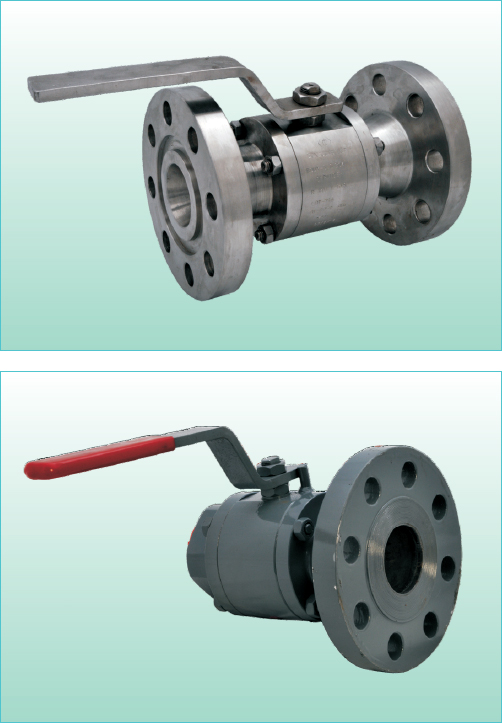

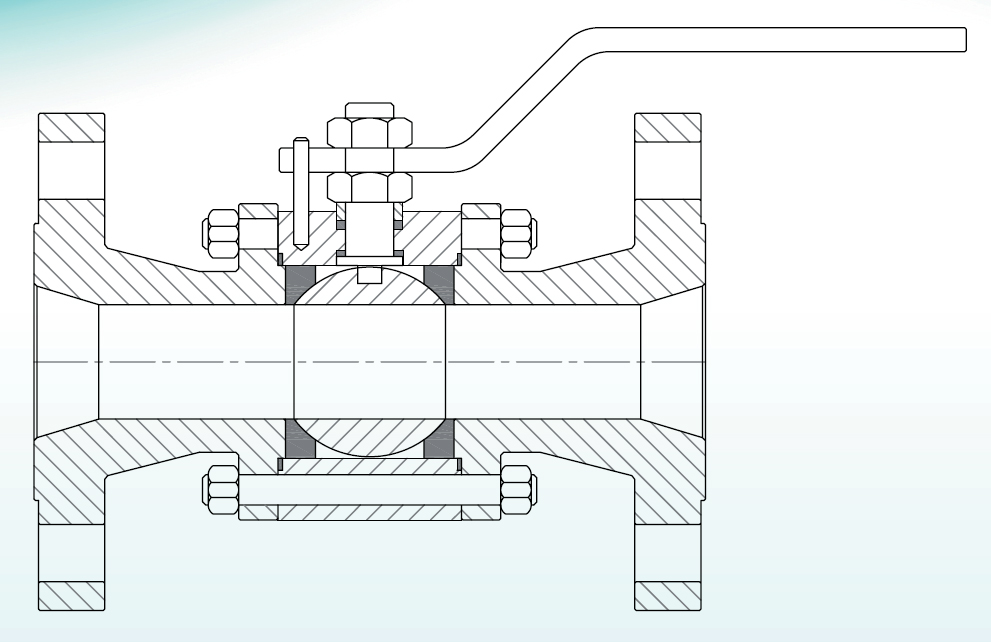

Ball Valves Download Brochure

Download Brochure

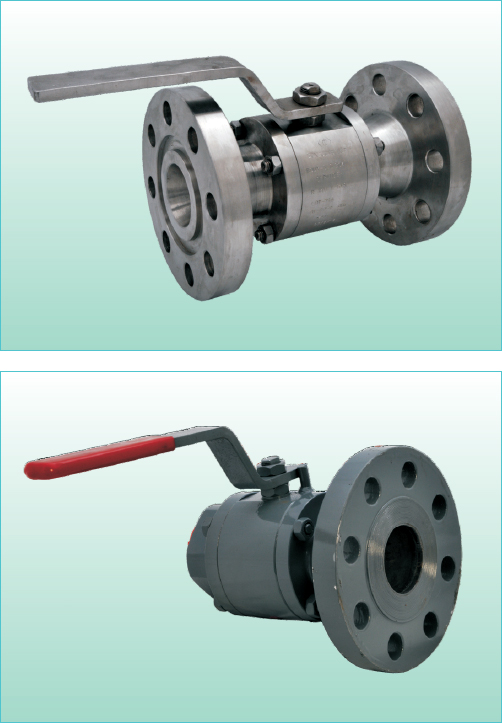

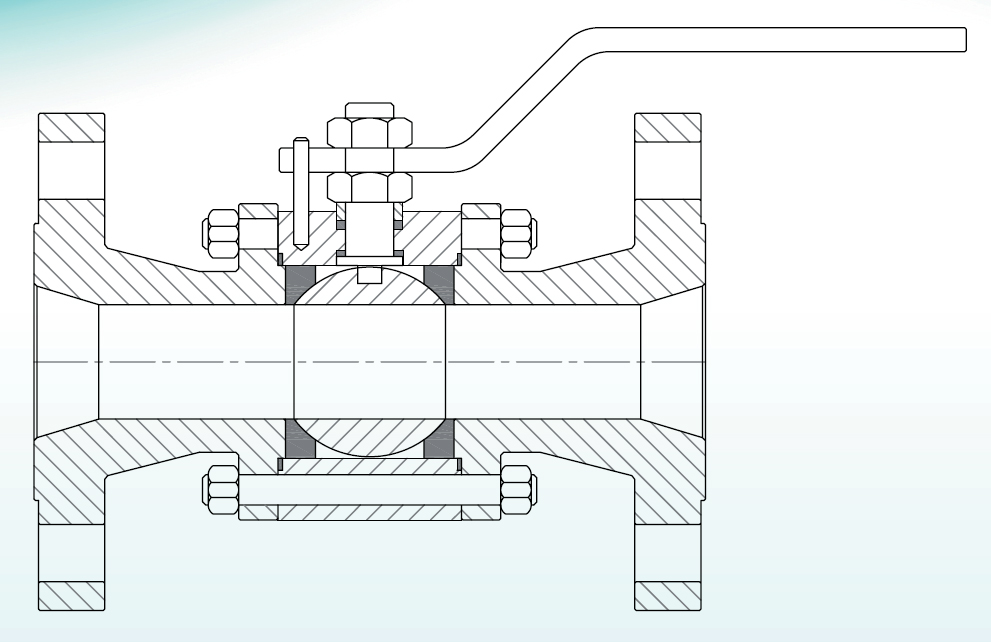

Application and Product Features :

- Suitable for high pressure - low temperature applications; Installed on mobile tank trucks / static installations; Pipelines and chemical / petrochemical process plants.

- Available in size range of ¼” NPT to 3” NPT in screwed end configuration and 15 mm NB to 300 mm NB in flanged end configuration.

- Manufactured for working pressures of upto 100 Kg/cm² (maximum) as per ternational codes and standards.

- Available in variable material of construction depending on service: ASTM A216 WCB, ASTM A105, ASTM A350 LF2, stainless steel, CF8M and brass.

- Used in LPG, Propane, Ammonia, Ethylene Oxide, Pentane, Oxygen, Nitrogen, Amines and Toxic / Permanent gas and high pressure applications.

- Available in reduced bore / full bore and single / two / three piece construction.

- Having a successful track record of last 30 years with over 80,000 valves in operation.

- Robust design with flexibility to tailor design to specific application.

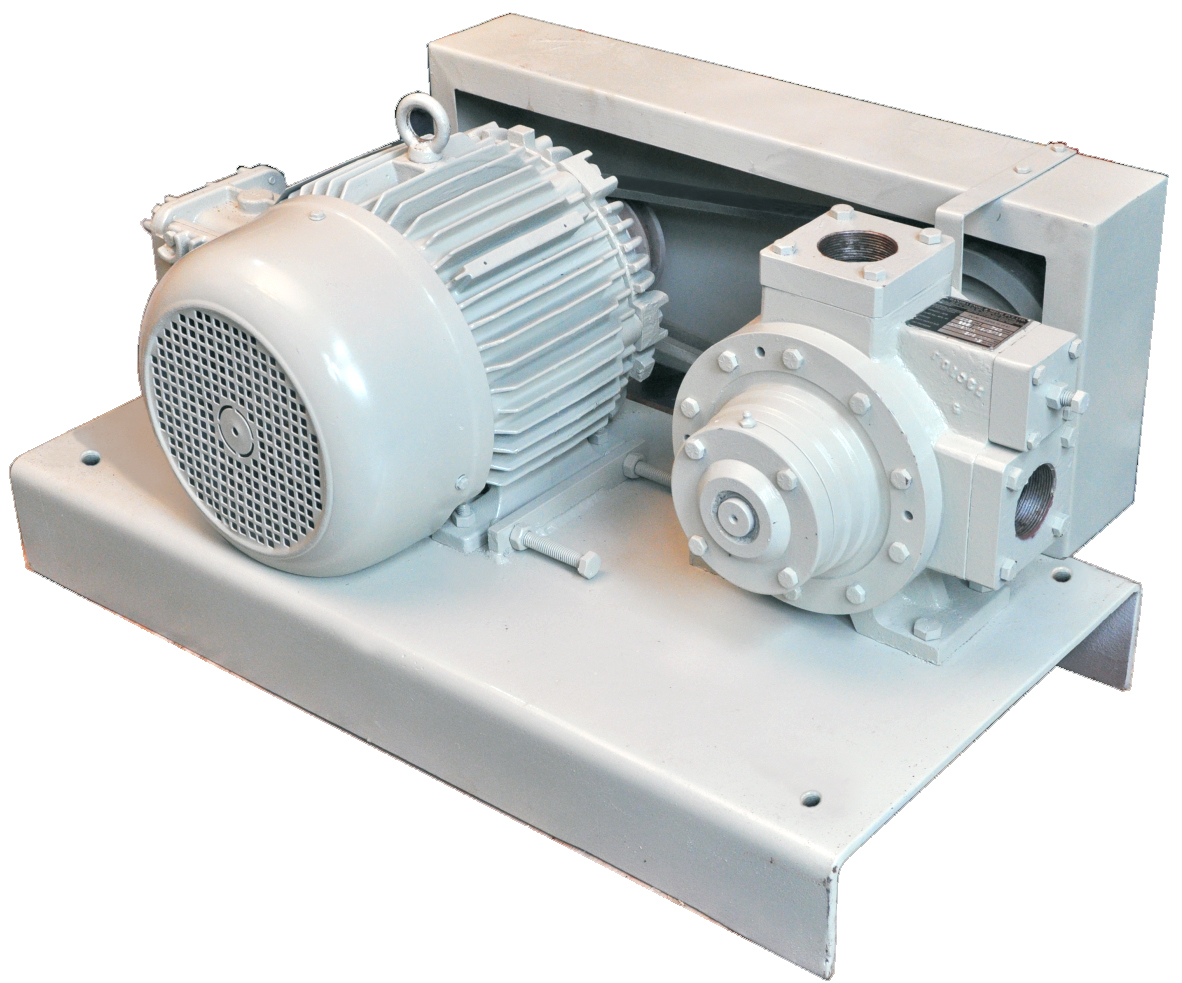

Positive Displacement Vave pumps Download Brochure

Download Brochure

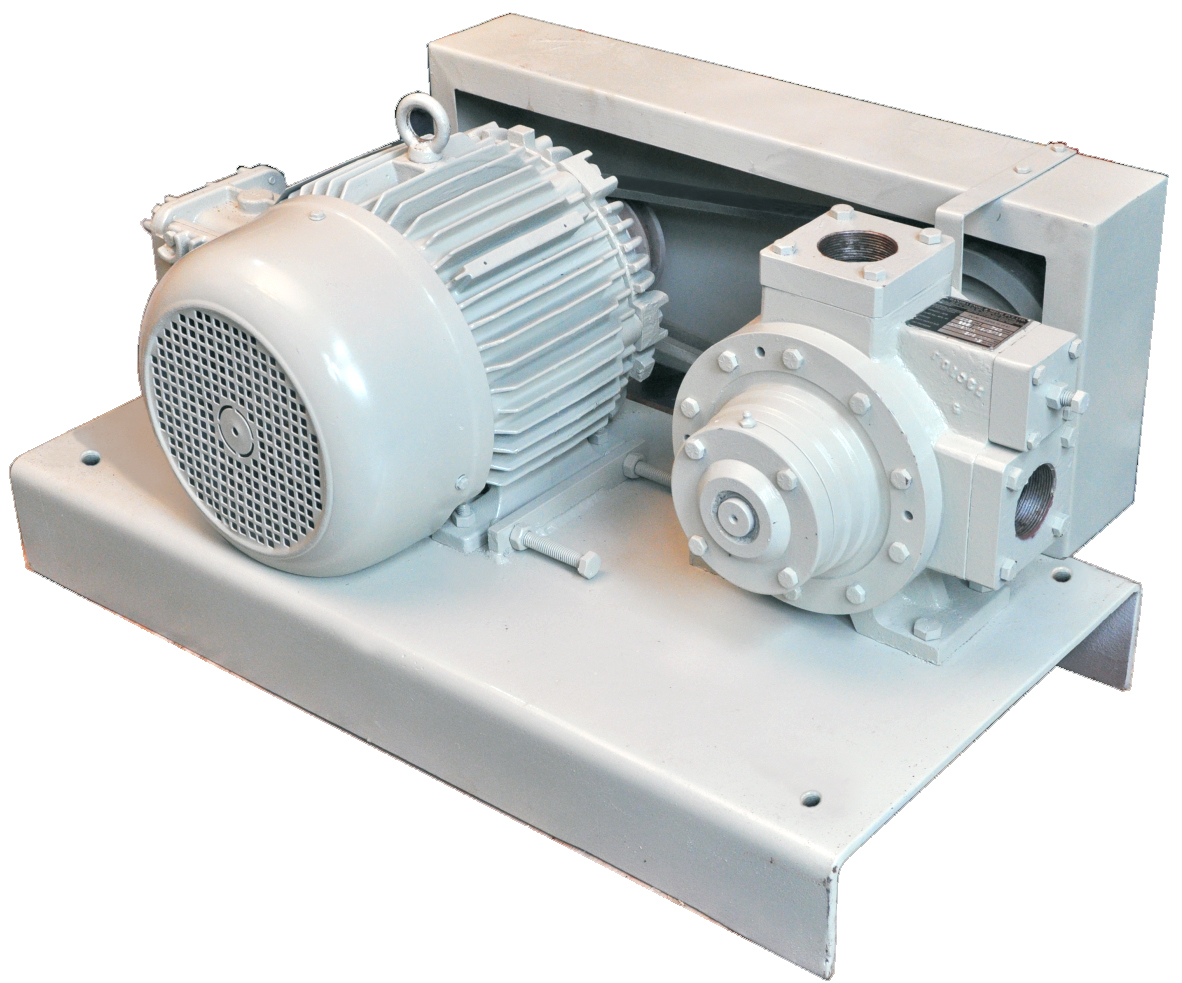

SERVICE : LPG / Propane / Butane / Ammonia

CAPACITY RANGE : 200LPM and 400 LPM

TYPE - POSITIVE DISPLACEMENT VANE PUMP

Application and Product Features

- Available in customized design for fluids like pentane, liquid fluids and chemicals.

- 100% indigenous design with easily available spares and best after sales support.

- High flow pumps suited for LPG, Propane, Butane and Ammonia applications for mobile tank truck unloading or transfer of product.

- Has internal by-pass and safety relief valve for over pressure relief for extreme safety in operation.

- Approved by the Chief Controller of Explosives, PESO, Nagpur (Government of India).

- Having excellent track record of trouble free operation at over 800 industries in the last 30 years.

- Fitted with flameproof motor with robust base frame.

- Most popular model 200 LPM pump has been in service at various prestigious industrial locations.

LPG/Propane/Ammonia vaporizers Download Brochure

Download Brochure

SERVICE : LPG / Propane / Ammonia

CAPACITY RANGE : 50 – 1000 Kg/hr

CONFIGURATION - a) Electrically Heated. b) Steam Heated. c) Hot Water heated.

Application and Product Features

- Widely used in industrial applications of LPG / Propane and LOT Installations.

- Having excellent track record at over 1500 industries where vapourizers have been operating for last 30 years.

- Robust design and 100% efficiency of rated capacity as designed for ambient temperature of 5°C.

- Stainless steel coil to ensure no issues of rusting in the 25 years operating life.

- Completely flameproof in construction and designed as per IS 60079-1, 2007.

- Approved by the Chief Controller of Explosives, PESO, Nagpur (Government of India).

- Has complete in-built auto shut off and controls, thus extremely safe for inflammable gas operations.

- Ready for installation skid : mounted on base frame for direct installation on flooring.

| Capacity |

50 Kg/hr |

100 Kg/hr |

200 Kg/hr |

500 Kg/hr |

1000 Kg/hr |

| Heater Capacity |

9 KW |

12 KW |

24 KW |

60 KW |

126 KW |

Turnkey Projects

for bulk storage of LPG , Propane & other products

Back Pressure Check Vavle

Excess flow check valve is installed as an emergency shut off valve to achieve safe control over fluid flow parameters of flow and differential pressure.

Product Features :

- Available in multiple configurations of screwed end, flanged end, sandwich type and no flow type for instrumentation nozzle.

- Available size range: ½” NPT to 4” NPT in screwed type, ¼” NB to 36”NB in flanged type, ½” NB to 16” NB in sandwich type and ⅛ NB to 2” NB size in no flow type.

- Primarily used in pressure vessels, pipelines, chemical plants, ship-shore line/cross country pipelines, bottling plants, loading arms, discharge lines of pump, petrochemical units and other applications.

- Applications in LPG, Propane, Ammonia, Ethylene Oxide, MMA/DMA/TMA, Chlorine, Propylene Oxide, Nitrogen, Oxygen and other compressed fluids.

- Safety device for auto shut off triggered by conditions of fluid flow and differential pressure across the valve.

- Available in various material of construction to suit fluid applications ASTM A216 WCB/ASTM A105/ASTM A350 LF2/stainless steel 304/316/316L and Monell to list a few.

- Designed as per international standards such as BSEN - 13175, Static and Mobile Pressure Vessel Rules (Unfired) 1981 and relevant safety codes and standards.

- Approved by the Chief Controller of Explosives, Nagpur (Government of India). Inspected/Certified by agencies of global repute, like EIL, RDSO, SGS, ABS & BV, etc.

- Manufactured and supplied around to 1,50,000 excess flow check valves in India and around the globe for a variety of applications in our 30 years experience in this field.

Technical Notes :

- 1) The excess flow valve permits the flow of vapour or liquid in either directions. The flow is controlled only in

one direction.

- 2) If the flow through the valve exceeds the predetermined value, the valve will shut off flow to ensure safety of the circuit.

- 3) The design of the excess flow check valve is made to suit client's requirements of flow based on process parameters of flow and ressure.

- 4) The excess flow check valve is designed for normal flow rate, peak operating flow rate and closing flow rate.

- 5) The closing flow rate is 20-25% higher than the peak operating flow rate. The normal operating flow rate is lower than or equal to peak operating flow rate.

- 6) Testing of excess flow valve is done using water as test medium following International codes & standards.

Thermal Relief Valve

Safety Relief Valves are spring loaded valves. They are used to provide over-pressure relief for the protection of the vessel / pipeline / tanks / process equipments from unsafe conditions. The valve normally remains in shut condition due to force of the spring and when there is a rise in pressure, the force of the spring is overcome actuating the valve to open condition to release the excess pressure.

Product Features :

- Available in multiple configurations of screwed end & flanged end (side discharge). Pop action safety valve which are used for instantaneous quick discharge are manufactured for typical TSV applications.

- Available size range: ¼” NPT to 3” NPT in screwed type, ½” NB x ¾” NB to 150mm NB x 200mm NB in flange type, ½” NPT to 3” NPT in Pop action safety relief valve.

- Primarily used in pressure vessels, pipelines, chemical plants, ship-shore line/cross country pipelines, bottling plants, petrochemical units and other applications.

- Applications in LPG, Propane, Ammonia, Ethylene Oxide, MMA/DMA/TMA, Chlorine, Propylene Oxide, Nitrogen, Oxygen and other compressed fluids.

- Safety device for over pressure relief is designed as per customer requirements of service, set pressure & sized as per relieving capacity requirement of the vessel / process.

- Available in various material of construction to suit fluid applications - ASTM A216 WCB/A105/ASTM A350 LF2/stainless steel 304/316/316L and Monel to list a few.

- Designed as per international standards, Static and Mobile Pressure Vessel Rules (Unfired) 1981 and relevant safety codes and standards.

- Approved by the Chief Controller of Explosives, Nagpur (Government of India). Inspected/certified by agencies of global repute, like EIL, RDSO, SGS, ABS & BV, etc.

- We have manufactured and supplied around to 1,00,000 safety relief valves in India and around the globe for a variety of applications in our 30 years experience in this field.

Sight Glaze for high pressure

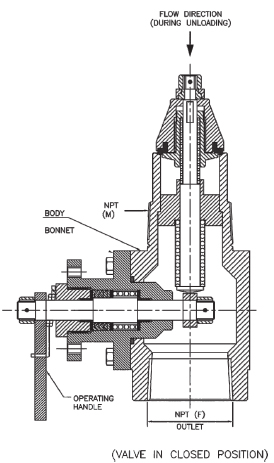

Internal excess Flow Check Valve Download Brochure

Download Brochure

Design Criteria

| EQUIPMENT |

INTERNAL EXCESS FLOW CHECK VALVE |

| MAKE |

CHANDRA ENGG. & MECH. PVT. LTD. |

| SERVICE |

LPG / PROPANE / PROPYLENE |

| DESIGN CODE |

STATIC + MOBILE PRESSURE VESSEL RULES (UNFIRED)1981; EN 12516-2; EN 13175 |

| DESIGN PRESSURE |

25.5 KG/CM² |

| TEST PRESSURE |

34.5 KG/CM² |

| TEMPERATURE |

- 42°C TO + 55°C |

| MODEL NO. |

SCR 50 & SCR 40 |

| SIZE |

2" NPT & 1-1/2" NPT |

| END CONNECTION |

NPT - SCREWED END |

| THREAD TYPE |

TAPER THREADS 11 ½ TPI |

Application and Product Features

- Approved by the Chief Controller of Explosives, Nagpur, (Letter No. PV(M)14/I dated 20.05.2013) for LPG, Propane & Propylene service as per EN/13175-2003 and Static & Mobile Pressure Vessel Rules (Unfired) 1981.

- Easy fitment onto existing mobile tank truck fleet without need for modifications/ alterations.

- Liquid Service: 2” NPT

- Vapour Service: 1.1/2” NPT

- Indigenously developed Robust Design suited for high performance under Indian operating conditions.

- Valves will be in closed condition during on-road transportation, thus eliminating risk of leaks in the event of any emergency.

- Higher flow rate during unloading operation to achieve shorter unloading time as compared to conventional valves.

- Has an In built 'Isolation Valve' thus adds tremendous safety to the output circuit.

- Low temperature steel body which ensures greater mechanical impact strength as compared to conventional brass excess flow check valves.

- Manufactured and tested as per international codes under renowned international third party inspection agency, like SGS India Pvt Ltd.

- Thermal link for auto shut off in the event of an emergency.

- Tamper proof design for trouble free operation for an extended service life.

![]() Download Brochure

Download Brochure

![]() Download Brochure

Download Brochure

![]() Download Brochure

Download Brochure

![]() Download Brochure

Download Brochure

![]() Download Brochure

Download Brochure

![]() Download Brochure

Download Brochure

![]() Download Brochure

Download Brochure

![]() Download Brochure

Download Brochure

![]() Download Brochure

Download Brochure

![]() Download Brochure

Download Brochure